Gervasi is a leading block making machines manufacturer.

Founded in 1992 by Moreno Gervasi, the company has always been synonymous with eco-sustainable development and research in automation.

Gervasi SPA has revolutionized the world of robotics in 30 years, thanks to the continuous collaboration with its customers with whom it has perfected its technology, making it flexible and attentive to operators’ needs.

CONCRETE BLOCK MAKING MACHINESFrom small local concrete block factories to the biggest plants in the world. The Gervasi block making machines series cover all types of concrete products and needs.

CONCRETE BLOCK MANUFACTURING EQUIPMENTGervasi equipments allow our customers to plan and scale their plants with automatic modules that covers all process, from the concrete plant to the product packaging.

CONCRETE BATCHING PLANT

High precise batching and mixing at any scale. Tailor-made for your plant-specific needs.

FLYING BUCKET

Free up space, reduce logistic costs and make aggregate transporting safer.

INNOVATIVE INDUSTRIAL SOLUTIONSOur core is the continuous work in industrial innovation and research, combining the reality of our customers with what will be the future of the industry in the coming years.

HEMPCRETE BLOCK PRODUCTION

Save the planet while investing in one of the most promising materials in civil construction for the next years.

SMART ENERGY

Achieve your eco-goals and reduce energy costs with our Smart Sunflower solar panels solution.

PELLETTIZER DISC – PAN GRANULATOR

2023 series of pan granulators, completely automatic and customizable. Mostly used in iron industries this series was developed following the high rate production mineral industries

METALLURGICAL INDUSTRY RECYCLING PLANTS

Fly ash briquette production and iron industry dust disposal systems

4.0 INDUSTRY AND RETROFIT SERVICESInterconnected, smart and reliable; thanks to the Gervasi team those are not only characteristics of the newer plants but also of older retrofitted machines

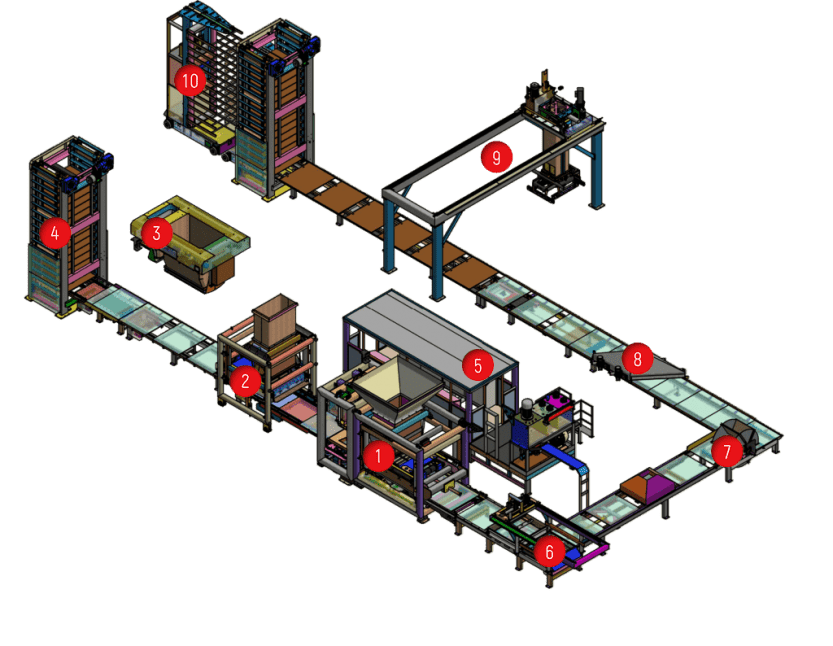

FULL AUTOMATIC LINEAR PLANTAll Gervasi products were conceived to be assembled in modular automatic plants, allowing it to be adapted to any space and workload.

Gervasi Block Machine complete line

Click on the machine of interest to discover more information about it, remember that you can always ask for help from our customer service!

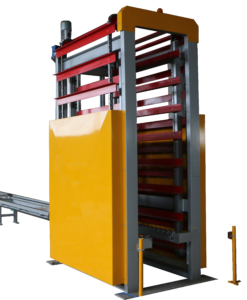

Elevator

This automated pallet Elevator, in couple with the Fingercar and the Lowerator will take care of the whole stocking and curing procedure.

Multilayer

This multilayer option allows the possibility to expand the production range by obtaining stratified products. This, among other things, allows you to have multiple colors pavers

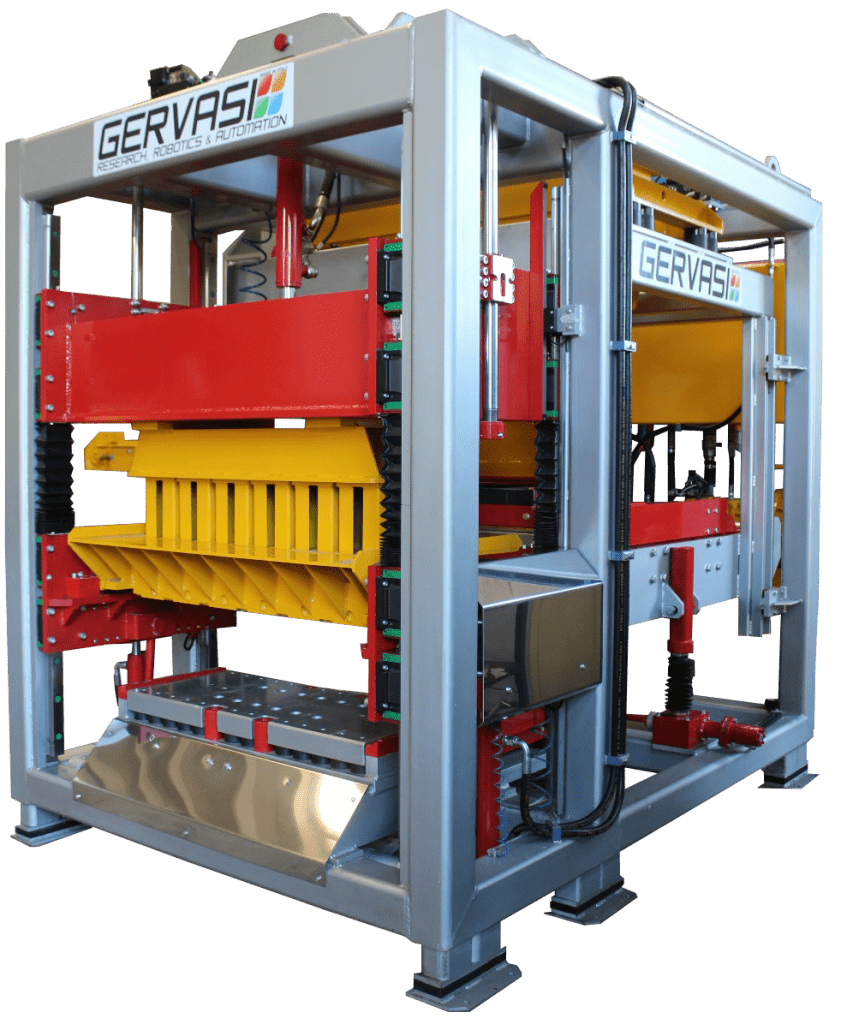

Block Machine

In the picture, the best selling vibropress, BX 1200.

The core of the system, fully integrated with the rest of the line.

Ask more informations to our customer service to have full support and informations!

Pallet table recovery system

This smart "Magnetic Robot", in couple with the pallet storage will stock and feed the cleaned tables to the vibropress at the desired rate

Turntable system

This simple but yet very effective operation will extend the life of your tables, optimizing the whole procedure.

Table cleaning procedure

Those brushes are the most important part in having a clean system, thanks to our experience the speed and the brushes are custom made to obtain best result in cleaning the tables, no matter the vibroformed materials

Control Room

"Brain" of the entire line our control room has been designed considering not only the technological integration and the possibility of centralizing the feedback from every part of the plant, but also the well-being of the operators, guaranteeing a clean and quiet place in which to work

GRK - Aerial Bucket

Space and energy saving this aerial hopper or "Travelling Bucket" it's the smartest way to transport concrete from the dosage line to the press unit

TR - Automatic transborder

Fully automatic, this heavy load transborder will take care of stocking fresh products in the curing rooms, unstocking dried ones and providing a continuous intake to the pallettization line.

ST - Heavy duty stacker

Always keeping safety first as a priority, this machine, being subject to severe wear, has evolved over the years to ensure the least possible maintenance using components of the highest quality

Why Gervasi?Founded in 1992 by Moreno Gervasi, the company has always been synonymous of eco-sustainable development and research in automation.

Located in more than 16 countries

Find the nearest production site and commercial office near to your plant.

Spare parts

Directly shipped from the nearest production site, or from our local warehouses.

Energy and Environment

Power up your machines with green energy thanks to our smart sunflower trackers.

Plan your growth

Find the right automation for your actual needs and plan your growth with us

Build your production facility with us

We help you plan your investment, even years in advance, to build the most efficient production site.

Fast shipment around the globe

In partnership with the best European expeditioner we provide fast and easy logistics even for the big plants.